It’s no secret that 3D printing has emerged as one of the most powerful technologies ever created, having the potential to disrupt and transform traditional manufacturing methods. With the right machines and materials, companies can today create all kinds of customized items in-house in a matter of hours. While this is revolutionary as it is, what’s even more novel is the penetration of 3D printing in the medical and dental industry.

Although there is still plenty of time before 3D printed output gets used in surgeries or for printing blood vessels and organs, they are becoming popular in digital dentistry already.

Challenges in the traditional methods

It is indeed shocking how the traditional workflow followed by most dentists today is so far behind in the high-tech world we live in. Take dental impressions for instance, which are the negative imprints of hard (teeth) and soft tissues in the mouth from which a cast is formed. Using this cast for fabricating the new tooth and having it fitted involves a lot of trial and error. Not to mention the duration of the entire process which is long and also uncomfortable or painful for the patients. In a report published by German O. Gallucci, it was found that the total treatment time of conventional impressive was 24:42 m/s while it was just 12:29 m/s (just about half) for digital impressions.

Enters Digital Dentistry

The dental industry has picked up the pace with technological advancements recently and emerged as digital dentistry. File-based products and procedures are only the beginning. There are better technologies along the line as well, which include 3D printing, robotic surgeons, and more.

The dental industry has picked up the pace with technological advancements recently and emerged as digital dentistry. File-based products and procedures are only the beginning. There are better technologies along the line as well, which include 3D printing, robotic surgeons, and more.

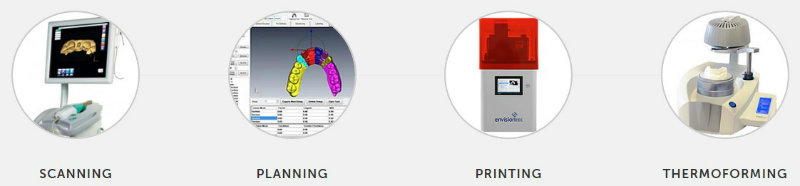

Today dentists are using digital technologies such as imaging for implant placements which are highly accurate, guided implant surgery with 3D printed surgical guides, 3D Printed Denture Bases and orthopaedic implants, etc. These technologies have made dentistry easier, faster, reliable, and cheaper.

Dental 3D printing

What digital dentistry is now, 3D printing will make it a hundred times better. For the first time ever dentists are able to produce custom and accurate dentures for their patients by using 3D scanners and 3D printers. However, that’s not all. Crowns, bridges, stone models, are some of the many possible orthodontic appliances that can be produced accurately and easily within minutes.

Popular 3D printing technologies in Dentistry

There are mainly four different kinds of 3D printing technologies used in the dental industry today:

- Digital Light Projection (DLP) 3D Printing: In this high definition projector is used to flash light-sensitive resin that’s held in a reservoir. The products are printed in layers.

- Jet (PolyJet/ProJet) 3D Printing: Its working is similar to inkjet printing. A resin is jetted onto support material and sprayed uniformly in layers.

- 3D printing Stereo Lithography Apparatus (SLA): A UV-laser is projected on and moved on the reservoir of a resin build material, illuminating and thickening the liquid resin only in the areas that are printed.

- Selective Laser Sintering (SLS): In this, a high power laser such as a Carbon Dioxide laser is used to fuse small particles of ceramic, glass, plastic, etc.

Picking a 3D Printer for Dentistry

It is one thing to pick a 3D printer for commercial printing collectables, and a totally different thing when you have to use it for dentistry.

Here are a few things you should keep in mind when deciding between 3D printer models for dentistry:

- Range of Materials: The printer should be able to work with common materials used in dentistry such as UV-sensitive liquid resin, dental plastic powder, crystal clear materials, etc.

- Software Compatibility: It should support specialized software for dental printing such as Exocad and Dental Wings, etc.

- Easy to Operate: The software interface used should be intuitive and easy to understand. It must also be able to print with a variety of materials without causing a lot of changeover waste.

One of the best 3D printers that check off all the bullet points above is the Envisiontec Dental 3D printer. It is specially designed for the orthodontic and dental industry and can produce well-finished prints in minimum time; giving one the possibility for transforming the traditional dental workflow to a digital one.

3D Dentistry today

3D printing has been expanding out from the industrial sector and making its way into the medical industry. Thus it is no surprise that Structo, a Singapore based company, has expanded its 3D printer lineup with a new and powerful machine – OrthoForm. It is a one of a kind wifi-enabled 3D printer that can work with a variety of dental software and file formats. It can print 8 moulds in 25 minutes which is a major advantage for dental surgeons for whom 3D printing speed is extremely important.

Realizing the potential of 3D printing technology government bodies and institutions in the field of education are also taking major initiatives. For instance, two prominent Singaporean institutes have joined hands to develop innovative products and devices that take oral health care to the next level. National Dental Centre Singapore (NDCS) and Nanyang Technological University (NTU) have partnered to provide training in research to dentists and opened a 3D printing research centre as well.

Conclusion

3D printing is revolutionizing the world, but it’s especially good to see that it has also paved a path for dentistry that will take it to new heights, and help overcome the shortcomings the industry was struggling with for many years.