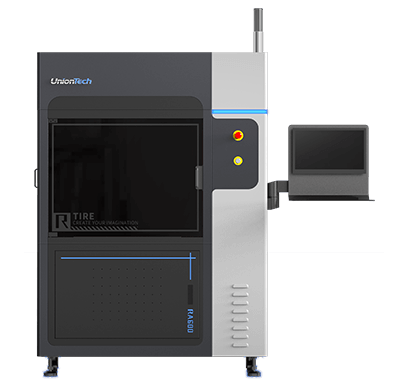

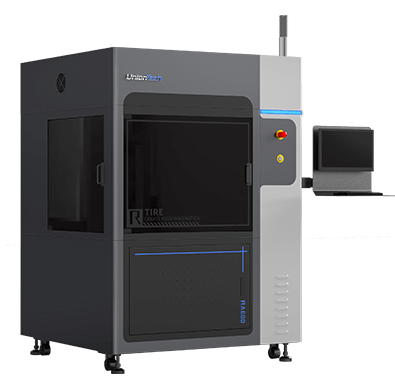

RA600

Tire Mold SLA 3D Printer

RA600 is made for tire molds, reproduces patterns perfectly, and it increases productivity while reducing expenses. Digital tire mold manufacturing based on 3D printing effectively shortens the lead time of the tire master mold and optimizes the process, reducing labor costs. The 3D printed tire master mold can present extremely difficult and complex patterns with a high precision of ± 0.1 mm.

Key Features

Smaller Size: Optimized design for specialized tire mold production helps reduce overall footprint and allows easier integration into existing manufacturing environments.

Highly Efficiency: Designed specifically for tire mold applications, it enables rapid printing with digital workflows that reduce lead time and labor cost.

More Stable: Built with high-end optoelectronic components and a closed-loop control system to ensure printing stability across complex geometries.

High Quality: Features automatic liquid level control and a negative-pressure recoating system to achieve consistent surface finish and mold definition.

More Precision: Dynamic variable laser beam, automatic calibration, and defect detection systems help maintain ultra-fine groove accuracy and dimensional precision.

Easy to Use: Seamless integration with UnionTech’s software ecosystem and simplified print management ensures a user-friendly, production-ready operation.

Applications

Precision Tire Mold Printing

The RA600 is engineered for the tire industry delivering unmatched accuracy in mold prototyping and production. With ultra-fine laser detail, dynamic beam control, and automated calibration, it reproduces complex tread patterns and groove geometries with ±0.1 mm precision. Streamline your mold workflow with digital, on-demand manufacturing faster, cleaner, and more cost-effective.

Specifications

Network

Ethernet, IEEE802.3, TCP/IP

Electrical Requirements

200–240 VAC, 50/60 Hz, Single Phase

Rated Power

2.6 kVA

Systems Control

Closed-loop

Temperature Range

72–79 °F (22–26 °C)

Maximum Change Rate

1 °C/hour

Relative Humidity

< 40%

Resin Vat

Replaceable / Fixed

Machine Dimensions

1375 × 1295 × 1930 mm

54.13 × 50.98 × 75.98 in

Machine Weight

850 kg

About Uniontech

Proven industry leadership

Founded in 2000, UnionTech is one of the earliest pioneers in 3D printing. With decades of experience and a strong global presence, UnionTech holds a major share of the industrial 3D printing market and is widely recognized for its innovation and reliability across multiple industries.

Integrated print ecosystem

UnionTech offers a complete additive manufacturing solution—3D printers, proprietary materials, software, and services—all developed in-house. This ensures seamless compatibility, efficient workflows, and consistent output quality across every stage of the production process.

User-friendly software tools

Polydevs and Unionfab ONE simplify the 3D printing workflow. From intuitive CAD model preparation to one-click automated printing, these tools improve speed, accuracy, and accessibility, making industrial-grade printing easy even for first-time users.

Material innovation

UnionTech invests heavily in material R&D through its subsidiary Synthestic. Their range of high-performance resins—polyurethane, thiol-ene, and special epoxy—caters to specific applications in dental, footwear, industrial design, and more.

On-demand manufacturing

Unionfab, UnionTech’s service platform, operates over 800 industrial 3D printers and offers rapid prototyping and batch production. Covering technologies like SLA, SLS, FDM, and CNC, it enables fast, cost-effective production of up to 100,000 parts with high quality.

Contact us for more info on Uniontech 3D printers, our experts are always happy to help