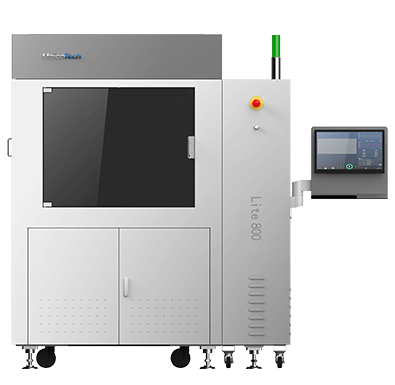

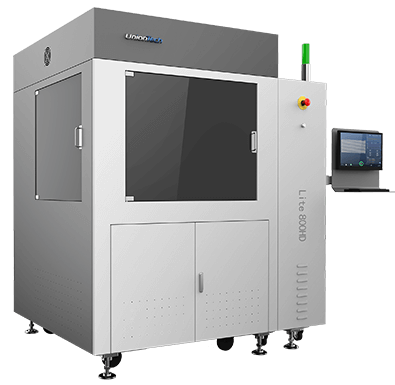

Lite 800

Industrial-grade SLA 3D Printer

Lite800 is an affordable large-format professional SLA 3D printer, compatible with a variety of 3D printing materials for large-batch printing. High efficiency, high precision, high stability. Using variable spot and split design to provide a one-stop solution for large-format integral printing, small-format for large-batch printing.

Key Features

High Stability: Featuring a closed‑loop control system and split design to enhance equipment stability for large-format printing.

Automatic Calibration: Factory-auto calibration and online laser measurement reduce manual errors and streamline setup.

Variable Laser Beam (Variable Spot): Dynamic and variable beam focus (spot size 0.12–0.8 mm) ensures flexible, efficient printing with consistent quality.

High Efficiency: Fast scanning speed (8–15 m/s) and large 800 × 800 × 550 mm build volume support high-throughput production.

High Quality: Innovative liquid level control, automatic recoating with negative-pressure scraper, and a reliable recoating system contribute to precise layer formation and surface finish.

Enhanced Precision: Impressive dimensional accuracy ±0.15 mm for parts <100 mm, and ±0.15% for larger parts; advanced optical components further refine accuracy.

Open Material & Parameter System: Supports a wide range of industrial-grade resins and fully customizable printing parameters.

Robust Construction: Designed to operate in controlled environments (22–26 °C, <40% RH, max 1 °C/h variation); solid-state 355 nm Nd:YVO₄ laser and Ethernet connectivity.

Applications

Industrial Part

Industrial Part

Decoration Part

Auto Lamp

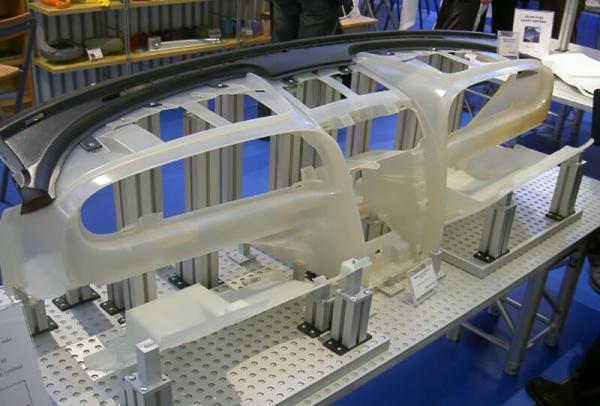

Automative Dashboard

Transparent Prototype

Transparent Prototype

Automative Parts

Specifications

Network

Ethernet, IEEE802.3, TCP/IP

Electrical Requirements

200–240 VAC, 50/60 Hz, Single Phase

Rated Power

2.8 kVA

Systems Control

Closed-loop

Temperature Range

72–79 °F (22–26 °C)

Maximum Change Rate

1 °C/hour

Relative Humidity

< 40%

Resin Vat

Replaceable / Fixed

Machine Dimensions

1555 × 1445 × 2215 mm

61.22 × 56.89 × 87.21 in

Machine Weight

1050 kg

About Uniontech

Proven industry leadership

Founded in 2000, UnionTech is one of the earliest pioneers in 3D printing. With decades of experience and a strong global presence, UnionTech holds a major share of the industrial 3D printing market and is widely recognized for its innovation and reliability across multiple industries.

Integrated print ecosystem

UnionTech offers a complete additive manufacturing solution—3D printers, proprietary materials, software, and services—all developed in-house. This ensures seamless compatibility, efficient workflows, and consistent output quality across every stage of the production process.

User-friendly software tools

Polydevs and Unionfab ONE simplify the 3D printing workflow. From intuitive CAD model preparation to one-click automated printing, these tools improve speed, accuracy, and accessibility, making industrial-grade printing easy even for first-time users.

Material innovation

UnionTech invests heavily in material R&D through its subsidiary Synthestic. Their range of high-performance resins—polyurethane, thiol-ene, and special epoxy—caters to specific applications in dental, footwear, industrial design, and more.

On-demand manufacturing

Unionfab, UnionTech’s service platform, operates over 800 industrial 3D printers and offers rapid prototyping and batch production. Covering technologies like SLA, SLS, FDM, and CNC, it enables fast, cost-effective production of up to 100,000 parts with high quality.

Contact us for more info on Uniontech 3D printers, our experts are always happy to help