QLS 230

Fast Cycle SLS 3D Printer

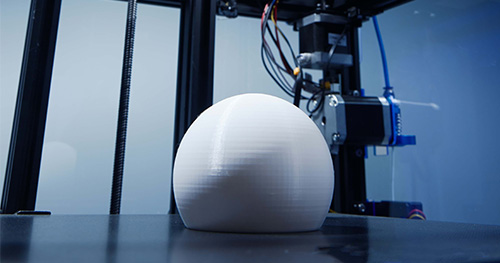

QLS 230 is the most affordable open platform selective laser sintering (SLS) 3D printer for industrial use. It provides a 24 hour cycle speed using a single 30 Watt CO2 laser to produce prototypes with robust mechanical and thermal properties. In addition to a broad range of high-temp thermoplastic materials, it excels with recycled powders from HP and EOS.

Key Features:

- Selective Laser Sintering (SLS) 3D Printer

- Build Volume: 230 x 230 x 230mm (9 x 9 x 9in)

- Build Speed: up to 20mm per hour

Printer Features

Increase Daily Output

With a cycle time of just 24 hours where the required cooling period is only 2 hours, the QLS 230 is a productivity powerhouse. It uses a single 30 Watt CO2 laser to increase your daily throughput without the need for a lengthy cooling period due to its smaller build chamber.

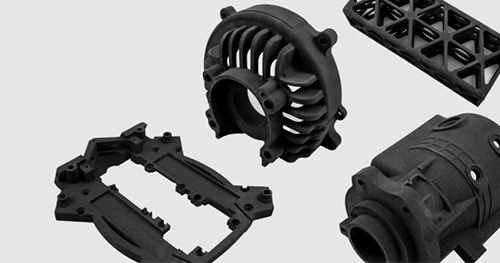

Material Flexibility

The QLS 230 is an open platform with 10+ qualified nylon and metal fusion materials. In addition to the currently qualified materials, it excels with recycled powders from HP and EOS for ultimate operational sustainability.

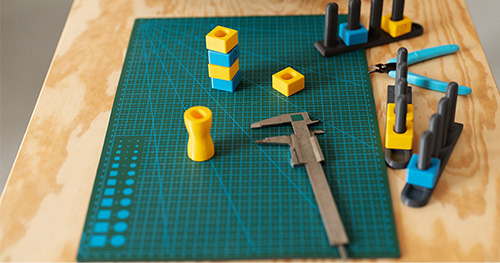

Lowest Total Cost of Ownership

With the lowest entry point in the professional selective laser sintering market, combined with lower operating costs due to its powder refresh rate of just 20% and use of third party materials, the QLS 230 offers the lowest total cost of ownership for your industrial SLS 3D printing needs.

Open Material Platform

In addition to accepting recycled powder from HP and EOS, the QLS 230 currently has 10 qualified nylon powders, including a range of Polyamides, PP, PBT, TPU, as well as the patented metal powders from headmade materials®.

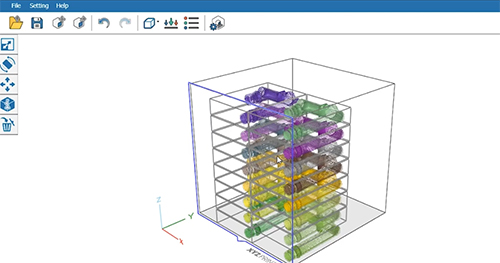

Intuitive Software

QLS 230 is powered by two advanced software suites, Buildware and XYZprint AMSLS. Buildware controls the sintering process while the XYZprint AMSLS allows users to start and monitor jobs remotely.

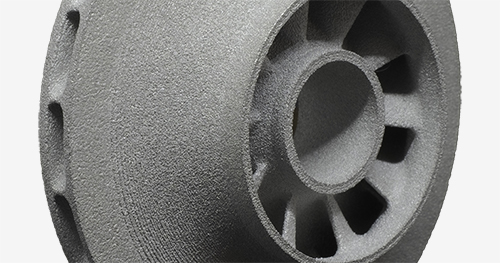

Cold Metal Fusion Compatible

Cold Metal Fusion by headmade materials® is a patented process that combines the advantages of fast cycle sintering with established powder metallurgy processes to create titanium and steel parts. Using a polymer-coated metal powder, the QLS 230 produces ‘green’ parts in a low temperature processing environment. Parts then go through a secondary debinding and sintering process that burns out any remaining polymer and sinters metal particles together to form final metal components.

Contact us for more info on Nexa3D printers, our experts are always happy to help

Contact us for more info on Nexa3D printers, our experts are always happy to help