Having difficulty with something as natural as walking or running may be news for you, but it’s a reality many people have to deal with every day. These are the people who suffer from medical problems such as soft tissue inflammation, plantar fasciitis, sciatic nerve, etc. that make the very act of walking in any kind of regular shoes painful or extremely uncomfortable. To alleviate the pain, they have to use specialized insoles and orthotic shoe devices.

Although there are over-the-counter shoe inserts commonly found in malls and local shoe stores, some people have to use a prescribed and customized product, especially when the problem is more complicated. This is where 3D printing can help, and let’s see how.

Taking Insole production to the next level

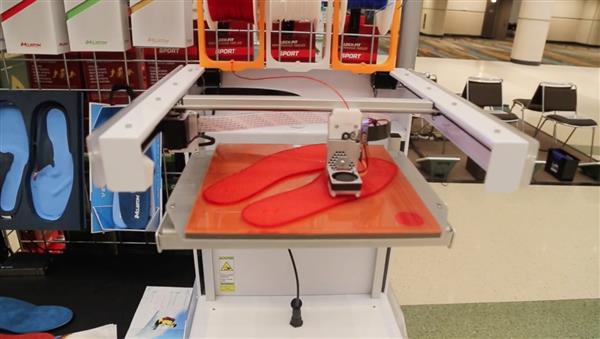

Traditionally orthotic insoles were hand-made by specialist shoemakers. Naturally, the process was quite tedious and time-intensive. More than that, imperfections in the final products were inevitable. However, with 3D printers, the shoemakers can produce the insoles not only accurately but also in a rather cost-effective manner.

One of the latest examples of 3D printing in the orthotic domain is the LAUF project, which in German stands for “laser-assisted construction of customized footwear”. The project is funded by Germany’s Federal Ministry of Education and Research through which they plan to digitize the entire process of insole making using 3D printing. With a newly developed software shoemakers will be able to design an insole for an individual patient and print out the result on a 3D printer at reduced costs and increased accuracy.

One of the latest examples of 3D printing in the orthotic domain is the LAUF project, which in German stands for “laser-assisted construction of customized footwear”. The project is funded by Germany’s Federal Ministry of Education and Research through which they plan to digitize the entire process of insole making using 3D printing. With a newly developed software shoemakers will be able to design an insole for an individual patient and print out the result on a 3D printer at reduced costs and increased accuracy.

Some companies that are already offering custom-made insoles include Wiivv Wearables, which broke the record as the Most Funded 3D Printed Good in Kickstarter history, and Gensole, which allows users to either upload their foot scan or use one of the templates available on the website to design their own insoles and have them printed.

How are 3D-printed Insoles made?

Customizing insoles is still a relatively new concept with only a few players offering it. Producers typically use a scan file of a person’s foot or use the foot impression on a polymer gel pad for reference. The second method, however, is quite complicated. In this, you have to use the casting or impression to start the 3D modelling phase. Then you have to take photos of the insole mould from different angles and stitch them together to create a 3D model using software (such as 123D). Once the 3D model is created you can export the STL file to 3D-print the insole.

The material used for printing may be an elastomeric polymer, a rubber-like texture that offers flexibility & support. When the insole is ready, a layer of micro fabric is added on top of it for comfort.

Future of 3D-printed Insoles

According to Nigel P. Beard, CTO of TN-based Feetz, one in three consumers are seeking personalization in their shoe purchases, and one in five Americans have foot issues that affect their shoe purchases. Thus, there is a lot of potential in 3D printed insoles and shoemaking itself. In fact, future directions for 3D printing could include making shoes that could offer gradual orthotic correction or use electronic circuits that can provide feedback on how the shoe is affecting gait.

The biggest challenge in 3D printed insoles today, however, its accuracy. A common way used is to scan a customer’s foot is by using a scanning device that is moved about the foot. However, the end scan results have errors almost always. Fortunately, a number of manufacturers and researchers are working towards improvements by refining the 3D scanning software and also the scanning method to a certain level to be able to provide custom insoles that fit like gloves. Without a doubt, this will be a great relief to those who have to make do with whichever insoles come close to a perfect fit today.